A SOPHISTICATED YOUNG ORIGIN

Fuadi plays many roles and wears many hats: he is a process designer, an importer, a dry miller, and a financier. He's also an academic and a great risk-taker. Thai coffee was relatively unknown in the international coffee scene before Fuadi and Jane created Beanspire in 2013. The increased production, accompanied by its processing innovation, is almost entirely thanks to Thai specialty roasters and the vibrant third-wave coffee scene. In fact, Thailand only exported 1% of its entire coffee production to the international market when Fuadi stepped in. Poised to bring these jewels to the specialty market, we cannot help but assume today's 10% is thanks to Beanspire.

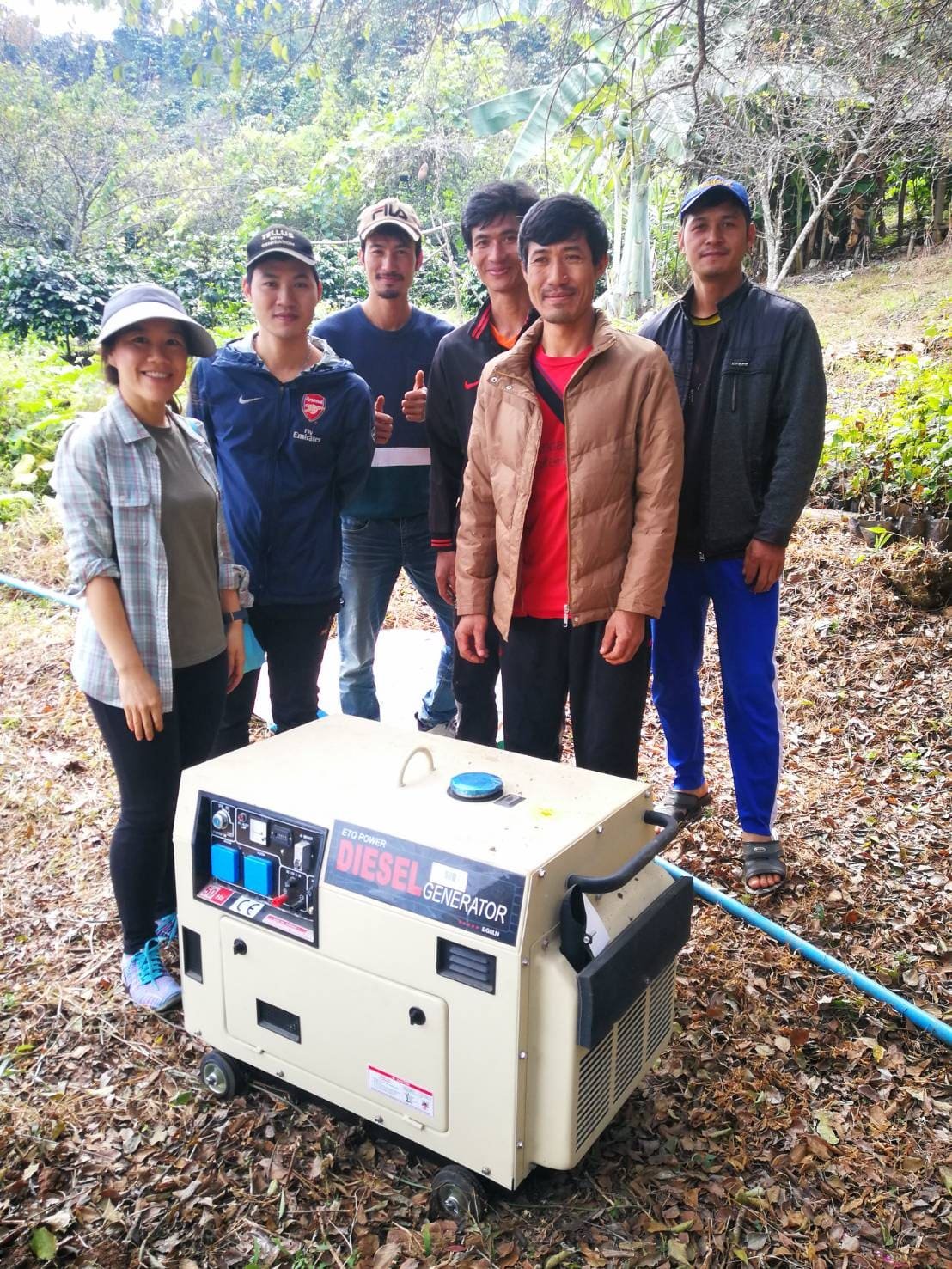

When we met in 2016, we were struck by Fuadi's commitment to the farmers, particularly with the hill tribe minority communities. He aimed to offer alternatives to them that could last, that offered security and lifelong stability. He also aimed to offer Thais coffee to the world.

Beanspire was born with a clear strategy and a vision: to work closely with farmers to improve processes and quality; to be the alternative for the younger generations of coffee growers; to become, ultimately, the financial solution for the farmers. We are honoured to sit at the table when designing this future for an origin unlike any other.

These are the 2022-2023 season Beanspire Coffee farmers.

Click on their pictures to read their full bio.

Beanspire works with approximately 50 different coffees and 68 households.

Noi Duongdee

Chaiprakarn

bags bought: 15

THIS SIDE UP VALUE CHAIN:

The price you pay: €10.90

CULTIVARS:

Red and yellow Catimor, Caturra, Bourbon, Typica, Catuai, Chiang Mai, SJ 133, Yellow Bourbon Mayaguez 139, High elevation Robusta, Chiang Mai 80

ALTITUDE:

400 – 1,500 meters above sea level. Note that at 19 degrees north of the equator, this elevation is really high for coffee (e.g. Colombia Narino is 1 degree north, Nicaragua is about 13 degrees north.) Coffee cannot grow in Thailand above 1550m.

NOTABLE:

Fuadi and Jane have created a well managed and organized company that is proving to be positive in the most misrepresented region in Thailand: the Golden Triangle.

Key Achievements:

2016 : first sales of Beanspire coffee (Doi Saket and Doi Pangkhon) in Europe

2017 : imported natural, honey and experimental lots from Saket. Visited Mr. Opp for the first time to discuss future cooperation Connected barista Rob Clarijs to Beanspire who competed with Thai coffee in the New York Masters, bought 60% more coffee from Beanspire compared to the year before.

2018 : Beanspire helped build a new, state of the art wet mill at Doi Pangkhon. Many roasters and traders went to visit Ata and Pupae, their coffee popularity has reached a tipping point as most of it sold out before it arrived in Europe. At Doi Saket they created an experimental semi washed lot that should combine the best traits of the washed and honey processes.

2019 : visits by by several of our roaster clients continued and around 90% of Beanspire’s harvest was sold directly to loyal fans throughout Europe.

2020 : prominent roasters like Has Bean started to carry Beanspire’s coffees in their assortment, further raising the origin to prominence, especially the processing innovation which has reached world standards. Added the Wiang Pa Pao blend to our assortment that serves as a more affordable espresso blend.

2021 : added six new farms to our assortment, firmly establishing Beanspire as a local curator of specialty coffees for the European market. During the pandemic, coffee sales did not suffer and even increased by 30%

2022 : first full container of coffee from Thailand for This Side Up. Revamped our Beanspire page to showcase many more of the farmers that Beanspire works with. This year, the total household count is 68, and the number of different coffees with different processing methods totals 50!

PROCESSING:

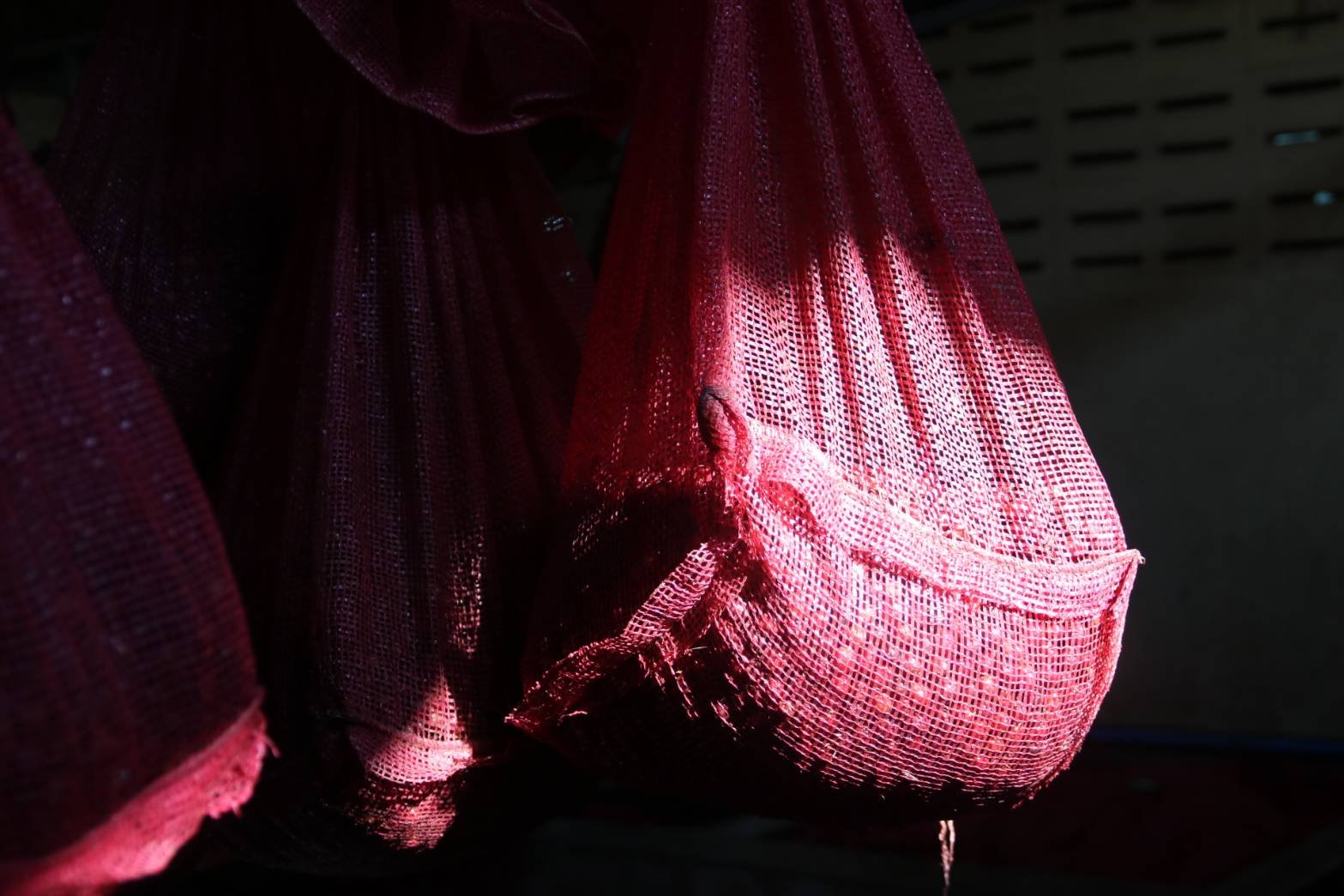

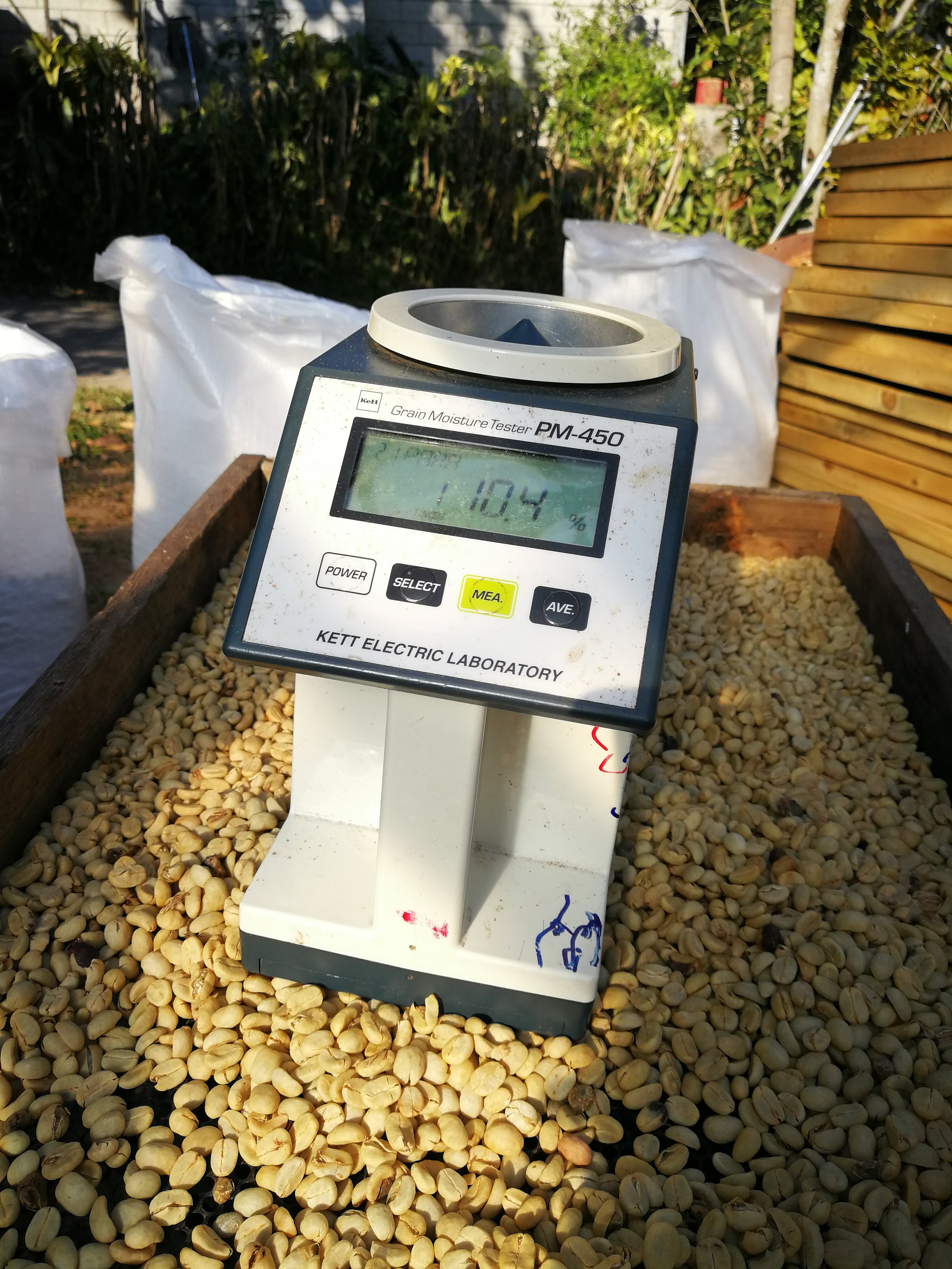

Natural: cherries were floated and laid on bamboo raised beds in a one-inch layer. Under-ripe and fermented cherries throughout the drying process were sorted, and the cherries were raked multiple times each day. After the cherries were dried, they're bagged to cure for two months before milling at Beanspires’ dry mill.

Kenya-style Washed: this coffee went through a double staged fermentation, which included dry fermentation, followed by wet fermentation, and soaking. Coffee was dried first on raised bamboo beds for at least 14 days, and lowland until the desired mouisture was achieved .

Black Honey: the coffee cherries collected towards the end of the season because of the slow ripening which is unique to Hua Chang. We pulped the cherries at night and dried immediate on raised beds to prevent fermentation. The drying house is designed so that the ventilation allows for slow and even drying. After drying, the parchment is delivered to our mill to be hull and sorted for export.

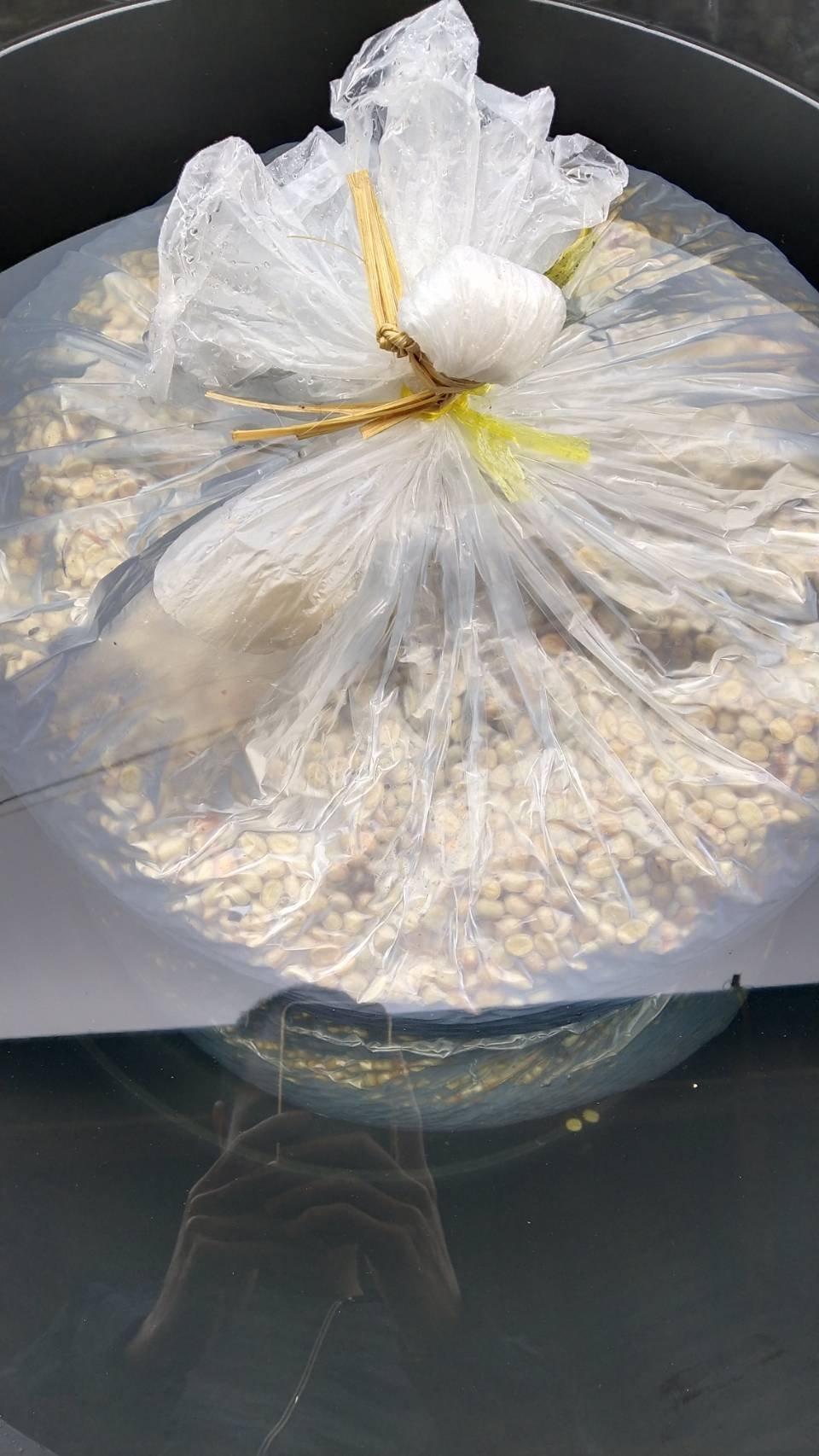

Natural Yeast Fermentation: coffee is inoculated with two types of yeasts: a yeast that is traditionally used for red wine, and a yeast used for white wine. Coffee cherries are fermented in closed tanks with a one-way valve, making sure the tanks are partially under water —in order to control the temperature. After 5 days, extra nutrients are added. This helps prolong the fermentation and yeast growth. Soon after, the second type of yeast is added into the tanks and cherries are left to ferment for an extra 5 days. After this, cherries are taken out of the tank and laid out on a thin layer on raised beds for 25 days until the moisture hits an appropriate level.

Sparking Natural: coffee cherries were fermented without water, using yeast that is typically used by Sauvignon blanc, creating an anaerobic fermentation environment. After three days, cherries were submerged in water and fermented further with a LALCAFÉ™ yeast, which has been selected especially for coffee. Lastly, cherries were fermented in an anaerobic condition for three more days.

**Beanspire is a true innovator in terms of experimentation. They manage other processes such as: Anaerobic White Honey, Double Anaerobic Honey, Anaerobic Black Honey and others.

DOI PANGKHON: €6,39

The price Beanspire paid the Merlaku family at Doi Pangkhon for their coffee wet parchment. The farmgate prices paid in 2022 for other coffees were:

Doi Pangkhon Natural: €7,86

Huai Mae Liam Anaerobic White Honey: €7,47

Huai Mae Liam Anaerobic Natural: €8, 75

Doi Saket Kenya-styled Washed: €7, 31

Doi Saket Anaerobic Fully Washed: €7, 31

Doi Saket Double Anaerobic Honey: €8, 14

Doi Saket Typica Anaerobic Natural: €8, 42

Doi Saket Yellow Bourbon Anaerobic Natural: €9, 25

Doi Saket Natural Controlled Yeast Fermentation: €8, 97

Doi Saket Koji Natural: €8, 97

Wynya Doi Saket Black Honey: €8, 97

Mae Suai Kenya Styled Washed: €6, 75

Mae Suai Natural: €9, 03

Khun Lao Black Honey: €7, 92

Khun Lao Natural: €9, 33

Wiang Pa Pao Fully Washed: €6, 75

Kra Buri Fully Washed Robusta - Nheng Khonlak: €5, 89

White Elephant Temple Natural Robusta: €5, 89

Mae Chedi Anaerobic White Honey: €8, 08

Mae Chedi Anaerobic Natural: €10, 47

Doi Phukkha Kombucha Anaerobic White Honey: €9, 3

Hua Chang Natural Yeast Fermentation: €9, 67

Beanspire: €1,66

This is the average price Beanspire gets for their work as exporter, coordinator, curator and development agent. This price includes their costs, such as coordinating the wet- and dry milling process, exporting and sea freight processes, as well as their profit margin. The margin for other coffees are:

Doi Pangkhon natural: €3,00

Huai Mae Liam Anaerobic White Honey: € 3,08

Huai Mae Liam Anaerobic Natural: € 2,71

Doi Saket Kenya-styled Washed: € 1,25

Doi Saket Anaerobic Fully Washed: € 2,15

Doi Saket Double Anaerobic Honey: € 2,96

Doi Saket Typica Anaerobic Natural: € 3,54

Doi Saket Yellow Bourbon Anaerobic Natural: € 3,85

Doi Saket Natural Controlled Yeast Fermentation: € 4,13

Doi Saket Koji Natural: € 4,13

Wynya Doi Saket Black Honey: € 2,71

Mae Suai Kenya Styled Washed: € 1,30

Mae Suai Natural: € 1,83

Khun Lao Black Honey: € 2,41

Wiang Pa Pao Fully Washed: € 0,63

Kra Buri Fully Washed Robusta - Nheng Khonlak: € 0,64

White Elephant Temple Natural Robusta: € 1,54

Mae Chedi Anaerobic White Honey: € 2,72

Mae Chedi Anaerobic Natural: € 2,75

Doi Phukkha Kombucha Anaerobic White Honey: € 1,49

Hua Chang Natural Yeast Fermentation: € 3,23

SHIPPING: €0,94

Sea freight from Bangkok to Rotterdam + clearance, local transport and storage.

THIS SIDE UP: €1,40

This is This Side Up highest possible compensation for spending time and resources importing this coffee. Our work includes building relationships with shipping and warehousing partners, managing export, import and shipping bureaucracy, Q grading, sampling and jointly promoting this coffee with Beanspire Coffee and Doi Saket coop members. For a full overview of what we do to earn our margin, see the Trade Models page.

FINANCING: €0,45

Average financing cost we have to pay social lenders and banks - simply because we don’t have the money in the bank to buy such large amounts of coffee all at once. This ensures immediate payment to Beanspire when the coffee leaves the port..

REGENERATION: €0,06

A standard TSU premium on all coffees designated exclusively to accelerate farmers’ own regenerative agriculture projects.

AVAILABLE FROM beanspire:

Doi Pangkhon Kenya-style Washed

Doi Saket Kenya-styled Washed

Doi Saket Anaerobic Fully Washed

Doi Saket Yellow Bourbon Anaerobic Natural

Doi Saket Koji Natural

Wynya Doi Saket Black Honey

Khun Lao Black Honey

Khun Lao Natural

Wiang Pa Pao Fully Washed

Kra Buri Fully Washed Robusta - Nheng Khonlak

Mae Chedi Anaerobic Natural

Doi Phukkha Kombucha Anaerobic White Honey

Hua Chang Natural Yeast Fermentation

RECOMMENDED IKAWA PROFILE:

We noticed in previous years that TSU Washed 1 wasn’t developing the beans as fully as possible so we tried Christopher Feran’s High Alt itude 1800m profile which gives fantastic results. We actually adapted our standard Washed profile to have a lower drop temperature (145 degrees Celsius) and a few more seconds total roast time so you can use both - they now develop acidities in these dense beans beyond citric into smooth malic flavours, allowing the chocolate body and layered sweetness to develop adequately. Cut the roast short if DTR exceeds 23%.

CONTACT THE PRODUCER

We communicate with Fuadi at Beanspire for all our practical dealings, but Ata and Pupae are more than willing to answer any questions you might have directly.

CONTACT Ata and Pupae Becheku / Fuadi Pitsuwan

EMAIL fuadi@beanspirecoffee.com

TEL +6682 191 4473 / +6602 594 3231

Doi Pangkhon, Chiang Rai Province, Thailand

Specialty Coffee from Thailand?

Thailand is not traditionally known as a specialty coffee producing country, yet it has been producing Arabica coffee since the early 80's. It started off as part of the Thai King’s opium eradication project. Because Arabica coffee thrives in a similar condition as opium, it was selected as a substituting crop against the cultivation of the illicit plant. Today, Thailand produces about 8,000 tons of Arabica coffee, mainly in the mountainous north of the country. On top of that, Thailand produces about ten times as much Robusta coffee, making it the third largest coffee producer in Asia. Thai specialty coffee is rarely seen in the top specialty roaster segment abroad. The main reasons for this are twofold. Thailand is a middle-income country and has a thriving local coffee market. That means relatively high production costs for a relatively undemanding coffee market.

Having said this, a strong specialty coffee segment is emerging. At least on the consumer side, the Third Wave is quite well established, with artisan roasters and cafés in Bangkok and Chang Mai. These roasters have recently begun to develop and buy local coffees too, not in the least because of import tariffs on foreign coffees. However, this scene is still very small and for now, hardly creates enough incentives for farmers to improve the quality of their coffee to specialty grade. So even though they have been doing a great job at pushing the limits of Thai coffee, the specialty coffee scene would be greatly aided with more specialty coffee knowledge and global integration.

Why We Care

This Side Up sees an important opportunity to showcase Thai coffee to the world's specialty coffee scene, not despite but precisely because of the higher production prices and living standards. Exposure to the specialty coffee phenomenon in relatively stable economies like Costa Rica and Panama has made them leaders in innovation, labour and environmental protection - and equally importantly, has made coffee farming, even on a micro-mill scale, lucrative for the next generation. On a larger scale, the gigantic coffee traders will eventually run out of cheap places to source bad coffee, and specialty coffee will surely continue to grow and disperse. These factors, in our view, mean that equality, quality focus and integration will slowly but inevitably become the future of the entire coffee producing world.

As a global society, we should be getting used to consumer prices that reflect a higher level of country development and social justice. We therefore have the ambitious goal to demonstrate, however small we are, that by kickstarting an increase in exposure and quality investment, stable Thailand and its young generation of coffee entrepreneurs could enter into a race to the top, become a country known internationally for its superb coffees - and in time set an example for all of East Asia.

Beanspire

Enter Beanspire, an exporting company made up of a group of young Thai specialty coffee enthusiasts who exist to provide a window for Thai specialty coffee smallholder farmers to the world. Their mission is much like that of This Side Up - but since they are mainly based in origin, our combined value was apparent from the start. Fuadi Pitsuwan was introduced to me by a mutual friend and tea expert, Janjarang Pat Kijitkhun and we quickly became sparring partners about the possibilities of Thai coffee in the European market. We decided to do a pilot project with the 2016 harvest aimed at attracting the interest not only adventurous roasters, but of other, larger importers as well.